Unlocking the Potential of Injection Mold China for Your Business

In today's competitive business landscape, the demand for high-quality products necessitates the use of advanced manufacturing techniques. One such technique that has gained significant traction is injection molding. Especially when sourced from reputable manufacturers in China, businesses can leverage this cost-effective and efficient method to produce intricate designs with precision and speed. This article explores the multifaceted benefits of injection molds in China, the manufacturing process, and how you can optimize your operations by partnering with an esteemed supplier like hanking-mould.com.

The Basics of Injection Molding

Injection molding is a manufacturing process that involves injecting molten material into a mold to create specific shapes and designs. This method is primarily used for producing parts from thermoplastic and thermosetting plastic materials. Its appeal lies in the ability to produce large quantities of parts that are consistent in quality and detail.

How Injection Molding Works

The injection molding process can be broken down into the following steps:

- Designing the Mold: The journey begins with designing the mold that matches the desired product specifications.

- Material Selection: Selecting the right material is crucial for achieving the desired properties in the final product, such as durability and texture.

- Heating and Melting: The selected plastic material is heated to a molten state in the injection unit.

- Injection: The molten plastic is injected into the mold cavity at high pressure.

- Cooling: The injected material cools and solidifies, taking the shape of the mold.

- Demolding: Once the part is sufficiently cooled, the mold is opened, and the finished product is ejected.

- Finishing Touches: Additional steps such as trimming, painting, or assembling can be applied to enhance the final product.

Why Choose Injection Molding from China?

As the world's manufacturing hub, China has established itself as a leader in the production of injection molds. Here are some compelling reasons to consider Chinese manufacturers:

Cost Efficiency

One of the primary advantages of sourcing injection molds in China is cost efficiency. Lower labor costs and material prices can significantly reduce the overall production expenses. This affordability enables companies to maintain competitive pricing in their respective markets.

High-Quality Standards

Many Chinese manufacturers have adopted international quality standards, employing advanced technology and skilled labor. Companies like hanking-mould.com ensure that their products meet rigorous quality checks throughout the production process, providing peace of mind to their clients.

Expertise and Innovation

The rapid growth of the injection molding industry in China has led to an increase in expertise and innovation. Manufacturers continuously invest in research and development to improve their processes and technology, ensuring they offer cutting-edge solutions to their clients.

Faster Turnaround Times

With a well-established infrastructure and efficient logistics, Chinese manufacturers are capable of delivering products at impressive turnaround times. Quick production and shipping processes can help businesses launch products faster, gaining an edge over their competitors.

Partnering with a Leading Manufacturer: Hanking Mould

Choosing the right partner is crucial for business success. Hanking Mould, a reputable plastic mold maker and plastic injection mould manufacturer, stands out in the industry for several reasons:

Comprehensive Services

Hanking Mould offers a wide range of services, from custom design and prototyping to mass production and post-processing. Their comprehensive service suite ensures that clients receive support at every stage of the manufacturing process.

Customization

Recognizing that every business has unique needs, Hanking Mould specializes in custom injection molds. Their team collaborates closely with clients to create tailored solutions that align with specific product requirements.

State-of-the-Art Technology

Utilizing the latest in manufacturing technology, Hanking Mould guarantees precision and quality in every mold they produce. Their commitment to innovation means that clients benefit from advanced manufacturing techniques that enhance product performance.

Commitment to Sustainability

In an era where sustainability matters, Hanking Mould prioritizes eco-friendly practices. They actively seek to reduce waste and minimize the environmental impact of their manufacturing processes, which can also be a selling point for businesses aiming to cultivate a positive brand image.

Applications of Injection Molding

The versatility of injection molding allows it to be applied across various industries. Below are some key applications:

Automotive Industry

- Production of dashboard components, panels, and brackets.

- Manufacturing custom parts for electric and hybrid vehicles.

- Creating durable and lightweight components to enhance fuel efficiency.

Consumer Electronics

- Casing for smartphones, tablets, and laptops.

- Custom parts for household appliances.

- Components for gaming devices and entertainment systems.

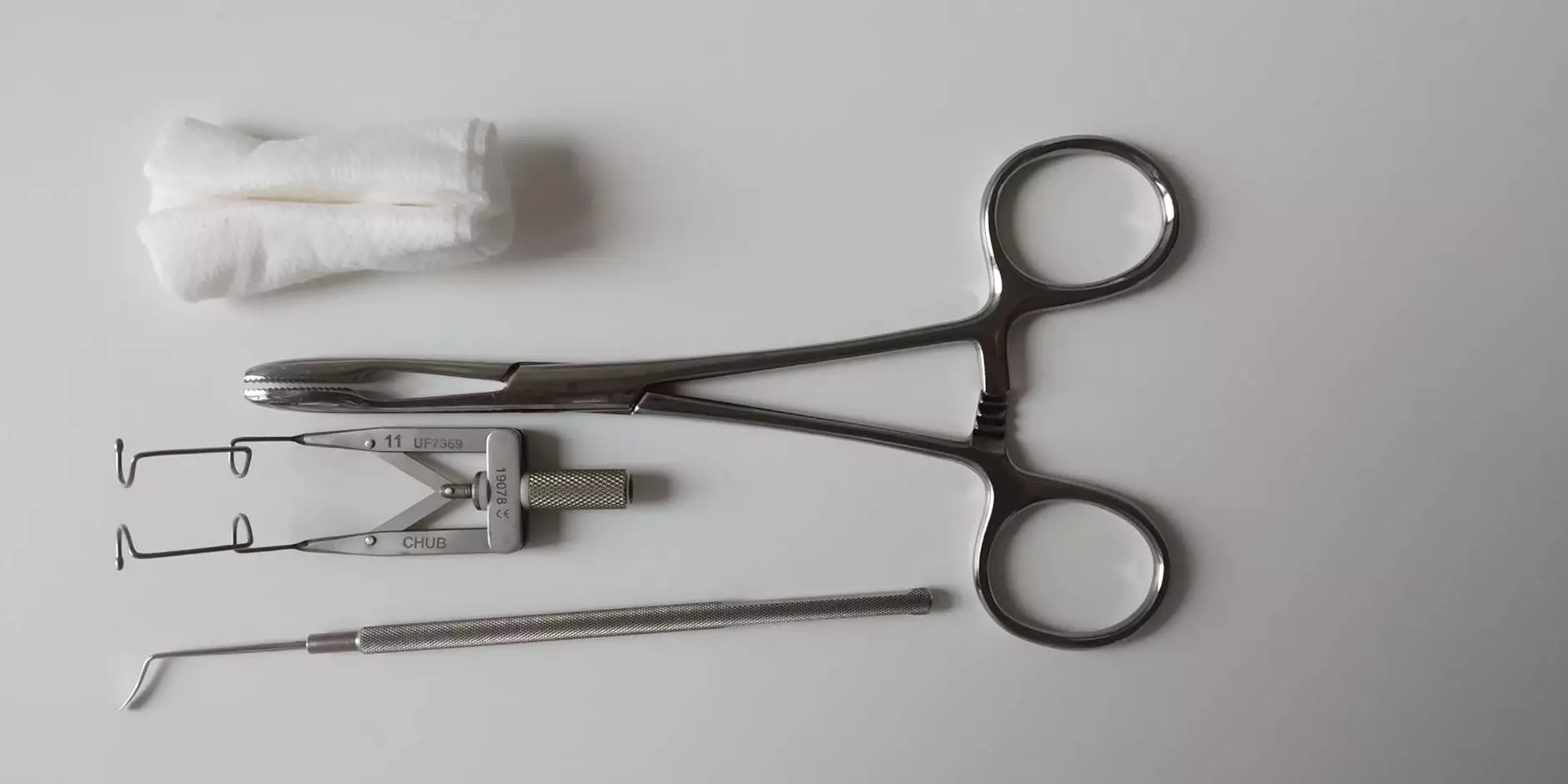

Medical Industry

- Manufacturing precise components for medical devices and equipment.

- Producing disposable items such as syringes and specimen containers.

- Creating ergonomic and user-friendly designs for patient care products.

Packaging Solutions

- Creating durable and attractive packaging for consumer goods.

- Manufacturing custom containers for pharmaceuticals and food products.

- Producing high-volume packaging solutions that maintain product integrity.

Conclusion

As you evaluate your manufacturing needs, consider the extensive advantages of injection molds from China. With a focus on quality, cost-effectiveness, and innovation, partnering with a skilled manufacturer like Hanking Mould can elevate your business operations and product offerings. By tapping into the potential of this advanced manufacturing process, you can not only optimize your production efficiency but also enhance your product quality, giving you a substantial competitive edge in your industry.

Embark on your journey towards business success by exploring how injection molding in China can reshape your manufacturing strategies and drive growth.

injection mold china