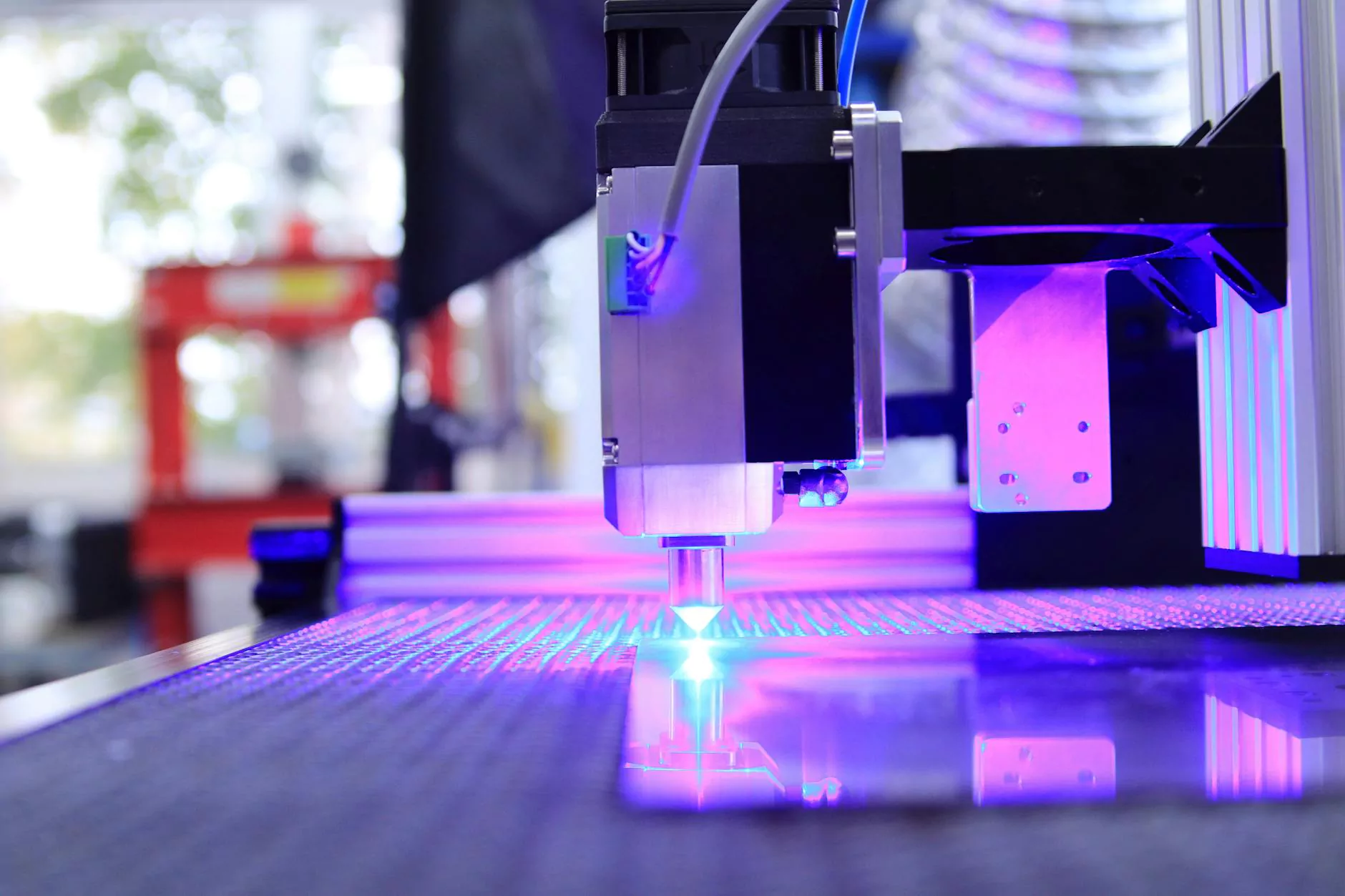

CNC Parts Factory: Elevating Metal Fabrication for a New Era

In the dynamic landscape of manufacturing, CNC parts factories are at the forefront of innovation and efficiency. By harnessing cutting-edge technology and engineering excellence, these factories are transforming how components are produced across various industries. In this extensive article, we will delve into the crucial role of CNC (Computer Numerical Control) in metal fabrication, explore the processes involved, and highlight how a commitment to quality at deepmould.net positions us as a leader within this domain.

Understanding CNC Technology

CNC technology has revolutionized the manufacturing landscape. It involves the use of computers to control machine tools such as lathes, mills, and routers. This precise control allows for the production of components with extraordinary accuracy and repeatability.

- Precision: CNC machines can produce parts with tolerances of less than a millimeter, making them ideal for industries that require strict guidelines.

- Efficiency: Automated processes reduce production time, allowing businesses to meet urgent deadlines without compromising quality.

- Versatility: CNC machines can work with a variety of materials, from metals to plastics, making them suitable for diverse applications.

The Importance of Metal Fabrication

Metal fabrication is a critical component of numerous industries, including aerospace, automotive, and construction. A CNC parts factory specializes in creating custom metal components that meet specific industry standards. Here’s why metal fabrication is so important:

1. Strength and Durability

Metals are known for their strength and resilience. Businesses in sectors where structural integrity is crucial rely on metal fabrication to produce parts that withstand rigorous environmental conditions.

2. Customization

In today’s competitive market, customization is key. CNC parts factories can create bespoke components tailored to the exact requirements of clients, ensuring they receive products that meet their unique needs.

3. Cost-Effectiveness

Although the initial investment in CNC technology can be significant, the long-term savings on labor, waste, and production times contribute to a lower total cost of ownership for businesses.

The CNC Parts Factory Process

Creating high-quality components in a CNC parts factory involves several essential steps:

Step 1: Design and Prototyping

The process begins with a 3D design created using CAD software. Engineers and designers collaborate to develop prototypes that are tested for functionality and performance.

Step 2: Material Selection

Choosing the right material is paramount. Factors to consider include:

- Mechanical properties: Strength, ductility, and toughness are assessed.

- Thermal properties: Resistance to heat can influence material choice.

- Cost considerations: The budget can dictate the selection of materials.

Step 3: Machining

Once materials are selected, CNC machines execute the production. Using the programmed instructions, these machines cut, mill, drill, and finish the components with unparalleled accuracy.

Step 4: Quality Control

A CNC parts factory must adhere to stringent quality control measures. Each component is meticulously inspected to ensure it meets dimensional specifications and tolerances. Advanced measuring tools such as CMMs (Coordinate Measuring Machines) facilitate this process.

Step 5: Finishing Touches

After machining, components may require additional processes such as:

- Deburring: Removing sharp edges to enhance safety and performance.

- Coating: Applying protective coatings for corrosion resistance.

- Assembly: Bringing multiple parts together to form a complete product.

Applications of CNC Parts Factories

The applications of a CNC parts factory are vast and varied. Below are some critical sectors that benefit from CNC technology:

Aerospace Industry

The aerospace sector demands components that meet stringent safety standards. CNC machining allows for the production of lightweight yet durable parts such as:

- Aircraft fuselage components

- Engine parts

- Landing gear assemblies

Automotive Sector

In the automotive industry, precision-engineered components are essential for performance and safety. CNC parts factories provide:

- Engine blocks

- Transmission cases

- Suspension parts

Medical Devices

The production of medical devices requires exceptional precision. CNC technology is used to manufacture:

- Surgical instruments

- Implants

- Diagnostic equipment

Why Choose DeepMould.net?

When selecting a partner for your CNC machining needs, consider the advantages that deepmould.net offers:

1. State-of-the-Art Technology

We invest in the latest CNC machines and software to ensure that we remain at the cutting edge of the industry.

2. Skilled Workforce

Our team of experts brings years of experience to the table, delivering quality craftsmanship in every project.

3. Commitment to Quality

At deepmould.net, we prioritize quality control and customer satisfaction above all. Each component undergoes rigorous testing and quality assurance processes.

4. Timely Delivery

We understand the importance of deadlines. Our efficient production processes ensure that your orders are fulfilled on time.

5. Competitive Pricing

We offer competitive pricing structures without compromising on quality, making our services accessible to businesses of all sizes.

The Future of CNC Parts Factories

The future of CNC parts factories is bright due to trends in automation and technological advancements:

1. Industry 4.0

The integration of IoT (Internet of Things) in manufacturing processes enhances efficiency and connectivity, leading to smarter factories.

2. Sustainable Practices

To reduce the environmental impact, CNC parts factories are adopting green manufacturing practices, utilizing recyclable materials and minimizing waste.

3. Advanced Materials

The development of new materials, such as composites, presents exciting opportunities for manufacturers, enabling the production of innovative products that were not possible before.

Conclusion

In conclusion, CNC parts factories are integral to the future of metal fabrication, driving progress in numerous sectors through precision and efficiency. By choosing deepmould.net as your partner, you gain access to unparalleled expertise, state-of-the-art technology, and a commitment to quality that ensures your business thrives. Embrace the revolution in manufacturing and explore the endless possibilities that CNC technology offers!